|

Главная |

Residual stress and Poisson’s ratio

|

из

5.00

|

Table of content

Introduction

Static model analysis

Proof mass

Suspension beams

Static deflection

Residual stress and Poisson’s ratio

Spring constants

Strain under acceleration 100 g and -100g

Sensitivity

Thermal noise

Resolution due to the ADC

Maximum acceleration

Dynamic model analysis

Etching time

Coefficients of basic equations

Natural frequencies

Damping ratios

Cut-off frequencies and squeeze numbers

Sensor system simulation

Equivalent circuits

Stability

Discussion

Introduction

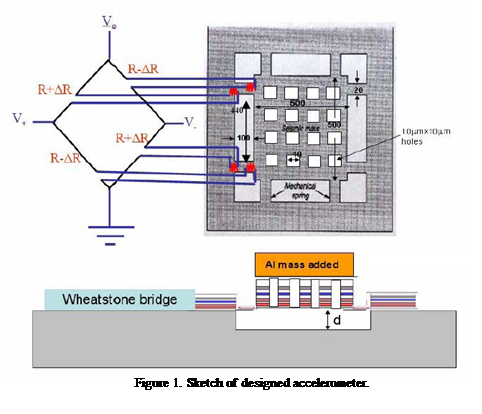

In this work possible design of accelerometer, which can be produced using MOSIS 2 poly and 2 metal process, will be considered. The not in scale sketch of accelerometer is presented in Fig. 1. To etch silicon under the proof mass post-process isotropic etching will be applied and some additional mass of Al will added by wire bonding in order to make total mass 10 times of the initial mass.

| |

Static model analysis

Proof mass

To make seismic mass of sensor as big as possible we should use all available layers. All such layers are listed in Table 1.

| Layer | Thickness, µm | Density, x103 kg/m3 |

| Overglass | 1 | 2.5 |

| Metal2 | 1.15 | 2.7 |

| Ox2 | 0.65 | 2.5 |

| Metal1 | 0.6 | 2.7 |

| Ox1 | 0.85 | 2.5 |

| Poly2 | 0.4 | 2.3 |

| Polyox | 0.08 | 2.5 |

| Poly1 | 0.4 | 2.3 |

| FOX+ThinOx | 0.6 | 2.5 |

| ∑ 5.63 |

Because there are sixteen etching holes in proof mass its total area becomes:

it is taken into account here that total mass is multiplied by 10 by adding aluminum layer above.

Suspension beams

Beams are very important part of accelerometer. Because geometry is already selected we only can choose now which layers we want to use. It is clear that it’s better to use one kind of material for beams in order to avoid residual stress due to different thermal expansion coefficient. So, only silicon oxide can be used. Some of possible combinations are listed in Table 2.

| № | FOX+ThinOx | Ox1 | Ox2 | Overglass | Total thickness, µm | z, position of poly |

| 1 | Ч | Ч | 1.25 | -0.025 | ||

| 2 | Ч | Ч | 1.45 | -0.125 | ||

| 3 | Ч | Ч | 1.6 | -0.2 | ||

| 4 | Ч | Ч | Ч | Ч | 3.1 | -0.95 |

Field and thin oxide have to be used because it is only protection for polysilicon piezoresistor from bottom side. From first three rows in Table 2 we can see that parameter z increases with increasing of thickness of silicon oxide above polysilicon, because it causes bigger strain. Making absolute value of z bigger sensitivity will also increased. So the biggest sensitivity can be obtained using the thickest beam, i.e. all layers will be used. It will be shown below that with such choice of beam structure piezoresistor’s polysilicon strain under acceleration 100g is lower then critical strain for polysilicon. It means chosen design satisfies original spec for our sensor to be able to measure acceleration in range ±100g.

Static deflection

To find static deflection of beam at x = Lb (for beams without residual stress)

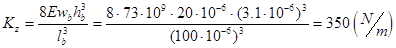

we need to know spring constant Kz. For chosen geometry of sensor it can be found as follows

Deflection will be found for conditions when accelerometer is under acceleration  and

and  .

.

To apply further analysis we must be sure assumption of small deflection is valid.

Obtained ratio is one order less then unity, so we can consider small deflection assumption is applicable.

Residual stress and Poisson’s ratio

The residual stress in any structure is usually due to “non-ideal” fabrication. It can cause some lateral forces acting on beams. Residual stress most commonly exists when two different materials are connected together because of different thermal expansion coefficients. So, in this work, because one type of material is used for beams influence of residual stress will be neglected (as it is done in previous section for deflection). But, in general, presence of residual stress will increase or decrease effective spring constant depending on direction of acceleration.

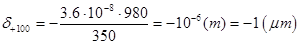

Generally, normal stress  and

and  in beams are related to the strain

in beams are related to the strain  and

and  like:

like:

where v is Poisson ratio. From equations above it can be seen that total strain can be affected by stress in normal direction. Influence of Poisson ratio may be considered in effective Young’s modulus

The correction term  can be found from Figure 2. Taking into account that

can be found from Figure 2. Taking into account that  and

and  , the aspect ratio for beam is

, the aspect ratio for beam is  and corresponding correction is actually very small. Together with small value of Poisson ratio v correction of effective Young’s modulus may not be considered. In further analysis Young’s modulus will be used without correction.

and corresponding correction is actually very small. Together with small value of Poisson ratio v correction of effective Young’s modulus may not be considered. In further analysis Young’s modulus will be used without correction.

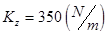

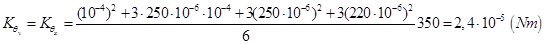

Spring constants

Spring constant for normal motion of proof mass was found earlier and equal to

Due to symmetric design of accelerometer lateral spring constants are equal and can be found from equation

|

из

5.00

|

Обсуждение в статье: Residual stress and Poisson’s ratio |

|

Обсуждений еще не было, будьте первым... ↓↓↓ |

Почему 1285321 студент выбрали МегаОбучалку...

Система поиска информации

Мобильная версия сайта

Удобная навигация

Нет шокирующей рекламы