|

Главная |

HEAT TREATMENT OF METALS AND ALLOYS

|

из

5.00

|

Heat treatment is a technological process involving the heating a metal part, holding it at a certain temperature and then cooling it to room temperature in order to attain desirable properties. The heating temperature is varied depending on type of heat treatment and material employed. The graph displays the temperature range of heat treatment for steel.

Heat treatment is a technological process involving the heating a metal part, holding it at a certain temperature and then cooling it to room temperature in order to attain desirable properties. The heating temperature is varied depending on type of heat treatment and material employed. The graph displays the temperature range of heat treatment for steel.

Tempering is applied to quench hardened parts in order to reduce brittleness and residual stress while increasing toughness. Additionally, the hardness and strength are decreased while the ductility increases with any increase of the tempering temperature.

Tempering is applied to quench hardened parts in order to reduce brittleness and residual stress while increasing toughness. Additionally, the hardness and strength are decreased while the ductility increases with any increase of the tempering temperature.

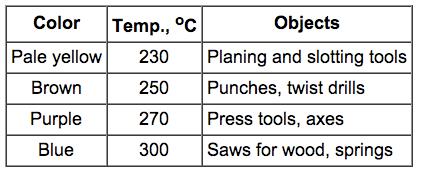

The colors that appear on a steel surface as the result of oxidation also differ with the temperature. The colors may be used as indicator to attain desirable properties.

The colors that appear on a steel surface as the result of oxidation also differ with the temperature. The colors may be used as indicator to attain desirable properties.

In plain carbon steel the maximum obtainable hardness is a function of the carbon content. A higher hardness can be obtained by increasing the carbon content. Cooling rate is an important parameter of hardening. By increasing the cooling rate of steel the resultant material becomes harder. The cooling rate depends on cooling medium and also the size and geometry of the piece. The fastest cooling is achieved using water, followed by oil and then air. Quenching agitation restrains the formation of a vapor coating on the surface of the piece in both water and oil and thus a higher cooling rate is attained.

In plain carbon steel the maximum obtainable hardness is a function of the carbon content. A higher hardness can be obtained by increasing the carbon content. Cooling rate is an important parameter of hardening. By increasing the cooling rate of steel the resultant material becomes harder. The cooling rate depends on cooling medium and also the size and geometry of the piece. The fastest cooling is achieved using water, followed by oil and then air. Quenching agitation restrains the formation of a vapor coating on the surface of the piece in both water and oil and thus a higher cooling rate is attained.

A round bar quenched from one end will show varying hardness along its length as the cooling rate changes. Hardenability describes the speed of this transformation. The hardness of steel with a high hardenability will change less rapid than that of steel with a low hardenability.

A round bar quenched from one end will show varying hardness along its length as the cooling rate changes. Hardenability describes the speed of this transformation. The hardness of steel with a high hardenability will change less rapid than that of steel with a low hardenability.

The alloying of steels increases their hardenability because the alloying elements permit more martensite to form at a given cooling rate.

Age hardening involves three stages:

Age hardening involves three stages:

1. An alloy is heated above the solvus line ab and held untill a homogeneous solid solution a is obtained.

2. Rapid cooling the alloy to preserve supersaturated solid solution.

3. Reheating the alloy to allow precipitation of very small crystals of the b phase.

The age hardening of alloys whose composition are located to the left of point a is impossible due to the inability to form a supersaturated solid solution.

Annealing is often used to soften a metal hardened through cold working in order to allow consequent forming. By combining drawing and annealing a fine wire can be drawn from a thick wire.

Annealing is often used to soften a metal hardened through cold working in order to allow consequent forming. By combining drawing and annealing a fine wire can be drawn from a thick wire.

|

из

5.00

|

Обсуждение в статье: HEAT TREATMENT OF METALS AND ALLOYS |

|

Обсуждений еще не было, будьте первым... ↓↓↓ |

Почему 1285321 студент выбрали МегаОбучалку...

Система поиска информации

Мобильная версия сайта

Удобная навигация

Нет шокирующей рекламы